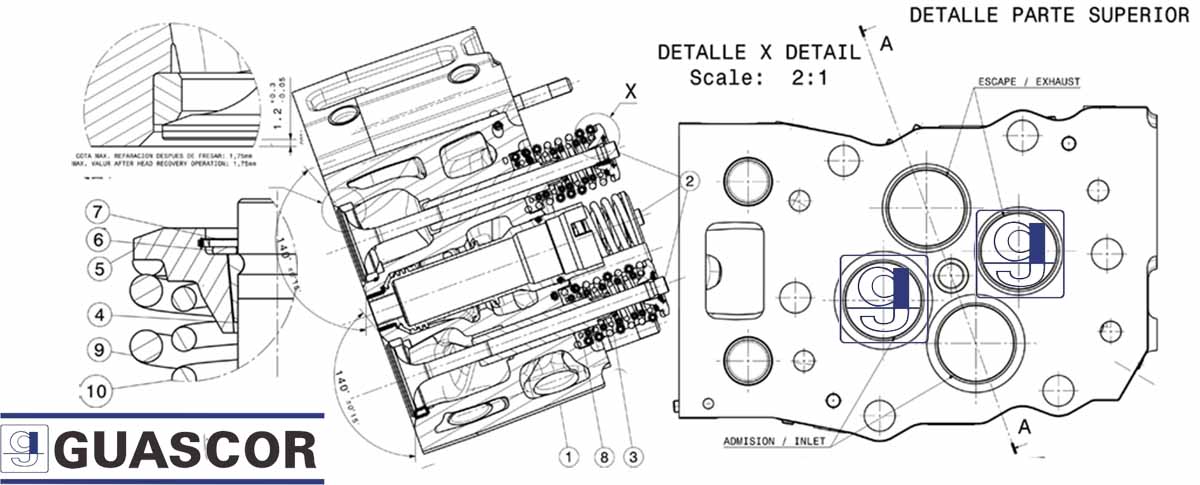

Dresser-Rand Guascor® SFGM Engine Series

The Dresser-Rand Guascor® electronically carbureted, Miller cycle, SFGM engine series ranges from 1055 to 1100 kWb. This engine series provides excellent installation solutions for power generation and co- and tri-generation configurations. These engines have been designed to operate using Miller cycle technology which provides maximum efficiency.

Output range from 1055 to 1100 kWb using natural gas

Output range from 275-906 kWb (1500 – 1800 rpm) using propane

Powered by natural gas, biogas, landfill gas, sewage gas, flare gas, and a wide variety of other gases – propane/ liquefied petroleum gas (LPG), syngas, associated petroleum gas (APG), well gas, etc.

Supplied as a stand-alone engine, genset, with cogeneration systems (CHP) skid separately, or in a fully assembled containerized unit (noise insulated if required)

Features include:

Dry exhaust manifold

Double step intercooler

Oil cooler in main / auxiliary circuit

194°F (90°C) main cooling circuit temperature

131 / 104°F (55 / 40°C) intercooler cooling circuit temperature

How does a Miller-cycle engine work?

The standard four-stroke engines are called Otto-cycle engines. They are named after Nikolaus Otto, who invented this type of engine in 1867. In the same way, Diesel-cycle engines are named after inventor Rudolf Diesel. Ralph Miller patented his Miller-cycle engine in the 1940s.

A Miller-cycle engine is very similar to an Otto-cycle engine. The Miller-cycle uses pistons, valves, a spark plug, etc., just like an Otto-cycle engine does. There are two big differences:

- A Miller-cycle engine depends on a supercharger.

- A Miller-cycle engine leaves the intake valve open during part of the compression stroke, so that the engine is compressing against the pressure of the supercharger rather than the pressure of the cylinder walls. The effect is increased efficiency, at a level of about 15 percent.