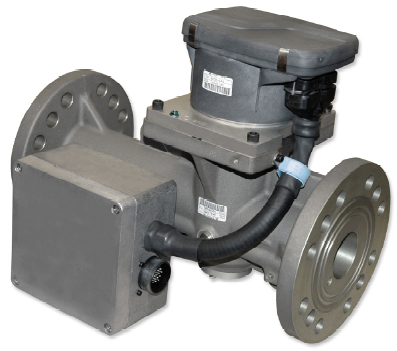

Woodward TecJet 52

Intelligent Electronic Metering Valve

Description

Efficiency, performance, and emissions. In today's marketplace, these factors play a key role in gas engine development. As engine performance advances are made, gas metering devices should be more flexible and accurate, and be used for a wide range of gas qualities from butane down to landfill gas.

Meet the TecJet™ valve. The TecJet is an electronic gas metering valve for singlepoint injection. It has integrated sensors and electronics, which provide the correct gas flow under all specified conditions. In general, a separate engine control system, like the EGS-02 control, calculates the desired gas flow from the different engine and gas parameters. This desired gas flow is transmitted through a CAN link to the TecJet valve(s). The TecJet valve ensures that the desired gas flow is attained, automatically compensating for changes in gas pressure and gas temperature.

The microcomputer inside the TecJet valve converts the desired gas flow signal and gas parameter information into a valve position (which corresponds to the desired gas flow), depending on gas inlet pressure, gas temperature, and the pressure difference across the valve.

Application

The TecJet™ valve, together with an engine control system, form an ideal combination for operating gas engines with a gas specific gravity from 0.4 to 2.0. The TecJet 52 gas control valve is applicable for stationary applications within a power range of 210–800 kW for low-BTU specialty gas and 500–1500 kW for pipeline-quality natural gas. This range is also dependant on other factors such as fuel pressure, fuel differential pressure across the valve, fuel temperature, etc. Consult the applicable TecJet Installation and Operation manual or a Woodward

application engineer for actual sizing of a valve.

The TecJet gas control valve is typically installed upstream of the turbo. The TecJet has a fast response to handle variations in engine load and speed. This is important for good engine behavior, low fuel consumption, low emissions and load changes. With the help of a PC (personal computer), you can easily monitor and set up the TecJet valve for your specific application.

Special features

• Improved vibration resistance over TecJet 50 Plus

• New platform allows for future performance gains & new applications or new processor

• Integrated return spring

• Forms ideal combination with EGS-02 control

• Bi-directional communication via CANbus, CANopen, J1939, or custom CAN

• Better dynamic response & repeatability over TecJet 50 Plus

• Accurate over entire flow range

• Flow testing ensures that the engine does not have to be recalibrated if TecJet is replaced

• Compensates for gas pressure and gas temperature fluctuations

• Wider range of installation options which include:

• Smaller and lighter than TecJet 50 Plus

• Can be supported by flanges

• Easier installation transition from TecJet 50 (original version) if space is limited

• Fully backward compatible with the TecJet 50 Plus