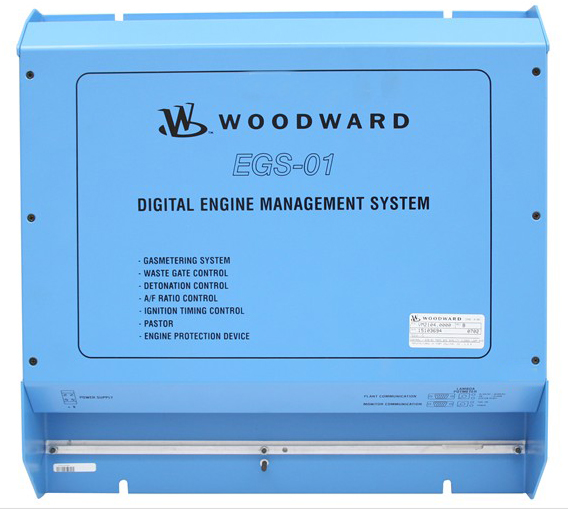

Woodward EGS-01

Digital Engine Management System

Part number: VM.2104

Efficiency, performance, and emissions are factors that play a key role in gas engine development. As engine performance improves, the need for a more accurate and flexible metering system such as an electronic control system is a logical step.

The EGS 01 is a state-of-the-art control module for stationary gas engines. It can be used to control the gas flow in relation to the air flow of an engine, at any load and speed condition. The EGS 01 control is capable of keeping gas engine emissions constant over a longer period of time. And the EGS control is not sensitive to the quality of the gas or the gas pressure and temperature. This is accomplished by the patented gas quality closed loop (lean burn) algorithm and lambda sensor aftercatalyst (lambda=1).

The EGS 01 control can be applied on in-line and V-type engines of any power output, naturally aspirated or turbocharged. The control can be easily programmed with the EGS monitoring program, and it covers the wide range of gas qualities, from landfill gas to propane. Even a significant change in gas quality during normal operation of the engine will be compensated for by the control.

Application

The EGS 01 control is applicable for stationary gas engines which operate in island mode or in parallel with the utility. The EGS control always works in combination with one or more TecJet controls. In general, the EGS calculates the desired gas flow from the different engine and gas parameters. This gas flow is transmitted through a CAN link to the TecJet control(s). The TecJet control ensures that proper gas flow is maintained, regardless of gas pressure and temperature.

The EGS 01 control can be used for:

• Single speed and variable speed engines

• Mono fuel, dual fuel, and variable fuel

• Mono control or stereo control on V-engines

• Engine protection, emissions control, and speed/load control

• ‘V’ and/or inline, 4-cylinder engine types

Benefits

• Improves engine stability, performance, and efficiency.

• Gas quality closed loop system with EGS/TecJet™ applicable on every generator set, resulting in low emissions without the use of oxygen sensors.

• Reduction of costs due to user friendly system for commissioning, diagnostics, and monitoring.

• Reduced number of parts. One venturi fits all applications and gas compositions.

• Control software, sensors, and the control module will always be the same. Only the size of the actuator is related to the engine output.

EGS-01 is obsolete therefore not available anymore. If you have trouble or malfunction with the installed unit you can send it us for repair or you can change it to EGS Full Authority.

How to change it?

Woodward’s EGS-01 control is no longer in production, and has been replaced by an updated EGS Full Authority. The EGS Full Authority replaces EGS-01 in Full-authority, Lambda >1, Mono-control systems.

The purpose of this application note is to provide guidance on retrofitting an EGS-01 installation or design with the EGS Full Authority. It is intended to supplement the EGS Control System Application Manual 26321, which details control installation, operation, calibration, and troubleshooting.

Assumptions

1. Customer has read the entire EGS Control System Application Manual 26321.

2. Customer has understood and complied with all of the warnings highlighted in the Manual 26321.

3. Customer understands that they are strongly encouraged and expected to thoroughly develop and test specific EGS control schemes for their gas engine application under normal and extreme operating conditions.

Introduction

Woodward’s EGS Full Authority can be used as a functional replacement for the EGS-01 control. The EGS Full Authority was designed with many new features and functions that are not built into the EGS-01. However, there are a few items that may need special attention to make the EGS-02 function in an EGS-01 system.

Differences Summary

Due to internal control design differences, the customer wiring to the control terminals is different. This application note illustrates the differences in wiring, sensors, communication interfaces, and Service Tool.

Input differences

|

Inputs |

EGS-01 |

EGS Full Authority |

|

Power supply |

Nominal: 10–32 Vdc, minimum 7 Vdc |

Nominal: 8–32 Vdc, minimum 6 Vdc; 15 W nominal (not including driven loads) |

|

Speed Sensor |

VR or Active Sensor |

VR or Active Sensor |

|

|

|

|

|

ALL ANALOG INPUTS |

Two-wire grounded or ungrounded |

One wire common return |

|

MAT |

PT-100 |

NTC |

|

MAP |

0–20 mA, 0–10 V or 0–5 V |

0–5 Vdc |

|

KW |

0–20 mA, 0–10 V or 0–5 V |

0–5 Vdc |

|

CH4% |

0–20 mA, 0–10 V or 0–5 V |

0–5 Vdc |

|

Load Reference |

0–20 mA, 0–10 V or 0–5 V |

0–5 Vdc |

|

Speed Bias |

0–20 mA, 0–10 V or 0–5 V |

0–5 Vdc |

|

Throttle Position |

0–20 mA, 0–10 V or 0–5 V |

0–5 Vdc |

|

Sensor |

|

|

|

Ignition Timing |

CAN/FireFly™ only |

External timing signal not available |

|

UEGO |

0–2.5 V, 0–5 V |

Needs Converter box for 0–5 |

|

|

|

Vdc signal input (NGK UEGO) or Bosch LSU 4.2 sensor |

|

|

|

directly |

|

Potentiometer |

Integrated into the control |

External 1 kΩ to 10 kΩ 3-wire |

|

|

|

pot |

|

Thermocouple |

Two (2) J or K type |

Cannot use thermocouple |

|

|

|

|

|

ALL DISCRETE |

0–6 V = FALSE |

Close to J1-A24 to activate |

|

INPUTS |

4-32 V = TRUE |

|

|

Circuit Breaker |

Not available |

Connect to Gen circuit breaker |

|

Aux |

|

aux, used for multiple dynamics |

|

Mains Circuit |

Close only when Gen & Mains is |

Connect to mains circuit |

|

Breaker Aux |

closed, used for activation of kW |

breaker aux, used for multiple |

|

|

load control |

dynamics and activation of kW |

|

|

|

load control |

|

Fuel On |

Activates control by opening throttle and TecJet™ |

Activates control by opening throttle and TecJet |

|

Raise/Lower |

Changes internal reference |

Changes internal reference |

|

Rated/Idle |

Changes internal reference |

Changes internal reference |

|

Fault Reset |

>10mA resets faults |

Standard DI resets faults |

Output differences

|

Outputs |

EGS-01 |

EGS Full Authority |

|

Throttle |

PWM - Push-Pull, 0–24 Vdc, |

PWM - Push-Pull, 0–24 Vdc, |

|

Command |

1000 Hz |

Frequency variable |

|

Wastegate Output |

PWM - Push-Pull, 0–24 Vdc, 1000 Hz |

PWM - Push-Pull, 0–24 Vdc, Frequency variable |

|

TecJet Power |

6 A steady state, 10 A peak for 1 |

None |

|

|

sec |

|

|

TecJet Keyswitch |

10 mA max, activates the TecJet when the engine is rolling |

Use one of the speed switch outputs and an interposing relay |

|

Fault Outputs |

Form C, dry contacts |

Low side relay drivers |

|

Major Alarm |

De-energizes on Engine Shutdown Condition |

De-energizes on Engine Shutdown Condition |

|

Minor Alarm |

De-energizes on Control Warning Condition |

De-energizes on Control Warning Condition |

|

CPU OK |

De-energizes on Control Watchdog Condition |

De-energizes on Control Watchdog Condition |

|

Speed Switches |

None |

Individually configurable for speed limit activation |

|

AUX Power |

5 Vdc, 70 mA for sensor power |

5 Vdc, 300 mA for sensor |

|

|

|

power |

|

LED Indications |

Power, Fuel On, Alarm, Shutdown |

None |

Communication differences

|

Communications |

EGS-01 |

EGS Full Authority |

|

Engine Control |

Custom CAN to TecJet(s) and |

J1939 CAN to TecJet(s), |

|

Network |

FireFly only |

FireFly, IC-920, easYgen™ |

|

|

|

3200, |

|

Plant Communications |

Modbus Slave, RS-232 DB-9M |

J1939 CAN, CANopen on rev B |

|

Service Serial |

RS-232 DB-9M, EGS DOS Tool |

RS-485 on main connectors, |

|

Port |

custom protocol |

ServLink for Toolkit |

Functionality differences

|

Functionality |

EGS-01 |

EGS Full Authority |

|

Speed Control |

Option |

Included |

|

Mono AFR System |

Option |

Included |

|

Stereo AFR System |

Option |

Not currently scheduled to include |

|

Single TecJet AFR System |

Option |

Included |

|

Dual TecJet AFR System |

Option |

Included |

|

Dual Fuel AFR |

Not included |

Option |

|

System – Fuel |

|

|

Replacing the EGS-01 Gas Engine Control with an EGS Full Authority Control System Application Note is available on requrest or you can download it from Woodward site.